Why you should also fly an APCO wing

APCO Aviation - World Leaders

APCO Aviation is one of the world’s leading producers of sport aviation equipment – paragliders for free flying and powered flying, as well as wings for powered parachutes, harnesses, rescue systems and accessories for our sports, and for UAV.

APCO has been producing world-beating products since the early 1970’s and continues to be the most veteran company in the field!

APCO remains at the leading edge of the industry for more than 40 years and our products hold over 16 World records and countless achievements on the national and international scene.

Click on the APCO logo below to visit APCO Aviation’s website, or have a look at a comparison of APCO’s wings.

APCO Aviation Head Quarters, Israel

Company History

APCO has been involved in the paragliding industry from the very beginning. Anatoly Cohn, the company’s owner and founder, started in hang gliding, designing and building gliders from 1974 with Agur Gliders until 1982 when he founded APCO. He quickly realized that paragliding was the direction for sport flying and concentrated on developing quality gliders at a competitive price. Since that time the company has steadily grown, employing now 60 people and produces thousands of paragliders, harnesses and parachute reserve systems every year.

The first paraglider produced by APCO was the 7 or 9 cell System K, staring in 1986. By 1996, a mere ten years later, APCO was producing an average of 3 new models a year and had already picked up 6 world records on its wings. A trend which was to continue into the next decade. By the beginning of 2006 APCO had brought out more than 40 models of paragliders and now has 11 world records set on APCO wings, an achievement yet to be equaled by any other paragliding manufacturer.

An APCO Aviation Showcase

The best testimony of a product is often to see it in action. Below are some great YouTube videos that showcase the most popular APCO wings in use today - for a comparison between all the models, click on one of the buttons above. We will introduce the entry-level wings first:

APCO F5 & APCO Lift (The best beginner and school wings on the market):

Until recently, the best beginner and training school wing has been the APCO Lift 2EZ. While it is still an excellent wing for beginners and schools, there is now also the F5. The F5 builds on the new technology developed for the F1 and F3 wings.

APCO F3 (Intermediate reflex wing)

The F3 is the new generation wing from APCO for intermediate pilots. It has excellent speed and maneuverability and is very well suited to cross-country flying. APCO lovingly refers to this wing as the “Baby F1”.

APCO F3 Bi (The best tandem wing on the market)

As its name suggests, the F3 Bi is a further adaptation of the technology developed for the F1 and the F3. Pilots who fly this wing are unlikely to want to fly anything else.

APCO F1 (Advanced wing - The fastest and most stable wing in its category on the market)

The F1 is an advanced wing meant for pilots who want to progress to the pinnacle of speed, stability, and cross-country flying. This wing is arguably the fastest paramotor wing on the market, clocking in at an incredible top speed of 80 km/h yet remaining stable and safe throughout its entire flight envelope. As discussed in the review video below, the F1 may not be the most agile wing in this class of wing as it is not a true slalom wing, but it is probably the most stable and safest wing compared to similar wings from other manufacturers. If you are looking for a fast, efficient, stable and safe cross-country wing that also offers plenty of agility, then the F1 may be your wing of choice. We highly recommend you watch the review video below.

APCO Nestra Light (New high-end EN-B glider)

The Nestra Light is APCO’s all-new high-end EN-B. A true cross-country machine offering C-level performance in the EN-B category with real-life B-level safety for any pilot looking for the best this category can deliver! Packed with technology, no effort was spared to give the Nestra Light the advantage that makes it top of its class. It is a TRUE 2.5 liner – the only wing in the B category to date! It is lightweight – starting from 4.35 kg, including standard risers. It features a 6.0 aspect ratio, impressive passive safety, and many other cutting-edge technologies!

Watch the Nestra Light in action on YouTube:

APCO Aviation Advanced Technologies

APCO Aviation has always been at the forefront of technology and has introduced many break-through inventions into the paramotoring and paragliding world. Below are just a few of the unique features you will find with APCO wings and paragliders:

MOHAWK® – Centre Stabilizer

Mohawk (pat. pending) is essentially a stabilizer positioned at the center of the canopy. Drawing inspiration from various fins and shares the same physical principles as a ship’s keel or airplane stabilizer.

The Mohawk measurably improves the wing’s roll stability and safety by acting as an auto stabilizing element whenever the wing is out of its flying axis.

The Mohawk has a great aerodynamic advantage over “winglets” in that it is aligned with the flow on all Angles Of Attack.

An additional advantage of the Mohawk is safety related. The Mohawk will make any wing exit out of spirals spontaneously with no pilot input which is a very important safety feature for all wings. Spiral exit is fast but calm, slowly dissipating the energy.

Made out of Superlight materials, the Mohawk is an inflatable structure and stays solid throughout the flight envelope.

Introduced by APCO for the first time in the industry, proving once again #ApcoAviationSettingFutureStandards.

A video explanation of this technology may be watched on YouTube.

BT2 – BUTT HOLE 2

Butt Holes 2 is the second generation of our original Butt Holes – exit points for debris from inside the wing. BT2 is essentially small holes located at strategic points of the trailing edge to allow sand and debris to exit from inside the wing with no pilot action. During normal use, the wing will collect sand and debris that accumulates in the corners of the trailing edge. This will negatively affect inflation and can be dangerous if the weight pushes the trailing edge down, essentially applying brakes!

To completely solve this issue, the butt holes are located at those points at which there is build-up, constantly releasing sand and debris, maintaining optimal flying characteristics. Especially useful for those who take-off in sandy areas. It is a “set and forget” feature which will make flying experience easier and safer. In other words, the connected panel through a 3D cut can no longer lay flat as a 2D piece of fabric, but is perfect as a curved 3-dimensional shape!

A video explanation of this technology may be watched on YouTube.

LDT – LOW DRAG TENSIONER

Drag reduction is one of the best ways to improve performance in any field fo aviation.

Our Trailing Edge Brake Tensioners have the lowest drag coefficient possible, while remaining durable and maintenance free.

Developed for our competition Paramotor wing, the F1, but now available on many APCO Wings.

A video explanation of this technology may be watched on YouTube.

EHP – EMBEDDED HOOK – IN POINTS

A typical glider has around 100 hook-in points, where the lines connect to its bottom surface. Each hook-in point creates a large amount of drag.

For many years APCO has been using its innovative EHP technology to reduce glider drag and improve performance.

Embedding top lines directly into the bottom surface of the glider, (using APCO’s EHP technology) will significantly reduce drag on each hook-in point to the absolute minimum. Multiplying this drag reduction over 100 line connection points results in a big performance gain. The improvement in performance is free of any side effects and is a very efficient way to gain on L/D without sacrificing safety or handling.

Traditional hook-in points are bulky tape loops with knots around them. They act as a forest of disturbances to the airflow under the wing, each creating turbulence around itself, contributing to a thicker turbulent boundary layer at the wing’s surface and greater drag.

A video explanation of this technology may be watched on YouTube.

FAR® – FLOW ALIGNED RIBS

Flow Aligned Ribs (FAR – pat. pending) is a conceptual change in the way paragliders have been designed until today (Apco and the rest of the industry).

Traditionally, due to a paragliders curvature / anhedral, ribs progressively become less and less aligned to the angle of airflow on the wing as you move closer to the wingtip. The FAR concept is, to gradually change the angle of the ribs so that they are aligned with the flow across the span of the wing. On wings designed using FAR, the ribs are positioned as normal on the centre of the wing, and gradually change direction towards the tips of the wing.

With the FAR rib layout, air flows over the wing without crossing ribs, and the flow “sees” the designed profile and not a distorted shape as it used to be until today. Wings designed using FAR, result in the cleanest most efficient airflow over the glider, reducing drag, minimising turbulent airflow and therefore increasing lift / performance.

For a greater understanding of the FAR design principle, watch the animation below. We believe that this concept will be embraced by the entire paragliding industry and that in a few years all wings will be designed in this way, as it is the correct way! This concept will gradually be implemented into our entire range of wings!

The Flow Aligned Ribs is another example of Apco Aviation setting future standards.

A video explanation of this technology may be watched on YouTube.

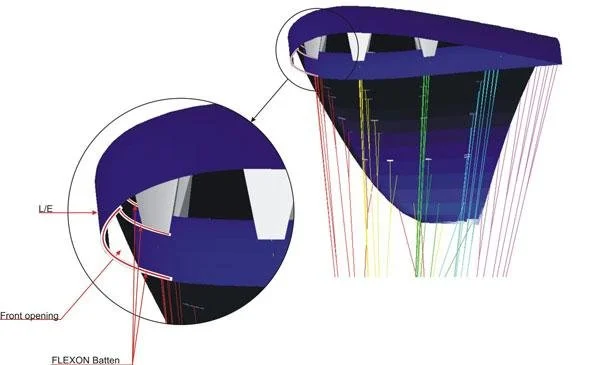

FLEXON® – BATTEN SYSTEM

A new generation FLEXON® batten system was incorporated (see below) for the leading edge of the ribs, ensuring perfect profile shape instead of traditional Mylar reinforcement. FLEXON® battens reduce the weight of the glider by an additional 500gr without any sign of deterioration during the life span of the glider.

Additional advantage of Apco’s FLEXON batten is that it is practically indestructable. With Apco’s FLEXON batten, there is no need for special care or folding methods. They always come back to their original shape, safeguarding the performance and launch over the lifespan of the glider

We guess you noted that recently, quite a few respected paragliding brands have borrowed the Flexon batten system for their products and claim to be the innovators, branding the system with fancy names.

How it works:

HIT VALVES – GREATER STABILITY AT HIGH SPEEDS

APCO’s HIT Valves are designed to improve the wing’s stability and performance at high speeds. The valves located on the leading edge will open automatically when the internal pressure of the wing drops, improving the stability of the wing. A few valves along the span of the leading edge are sufficient to pressurise the entire wing during accelerated flight or loss of internal pressure. HIT valves – another exclusive innovation from APCO often copied, never matched.

A video explanation of this technology may be watched on YouTube.

OAA – ONE ACTION ACCELERATION

OAA is an innovative system. The OAA allows to simultaneous operate both the speed system and the trimmer for the optimized angle of attack at any given speed. With OAA, when using the speed system, the trimmers are released gradually according to the position of the speed bar. This allows for a larger speed range that can be fully used in one swift action of the speed bar.

A video explanation of this technology may be watched on YouTube.

PBH - PARAMOTOR BRAKE HANDLE

Our Paramotor Brake Handles (PBH) are the result or years of experience and testing. They may look like any other handle, but they will keep you safer in the air. The design helps prevent the handle from being sucked through the mesh of the cage into the propellor, which can have fatal results. The stiffener in the handle can be removed, and it will still offer good resistance to passing through the mesh due to the foam stiffeners in the sides, however, we recommend flying with the stiffeners for motorised flight.

A video explanation of this technology may be watched on YouTube.

RCB – ROLLER CAMET BUCKLE

RCB – Roller Camet Buckle “Paracam” is an innovative new type of Cam buckle. Used to operate the trimmers, it drastically reduces friction, giving a huge advantage in functionality and ease of use:

Effortless closing of the trimmers – Even with the heaviest applications such as trike or tandem flying.

Controlled and gradual release of the trimmers – one-hand operation.

Small details make a perfect package.

#ApcoAviationSettingFutureStandards

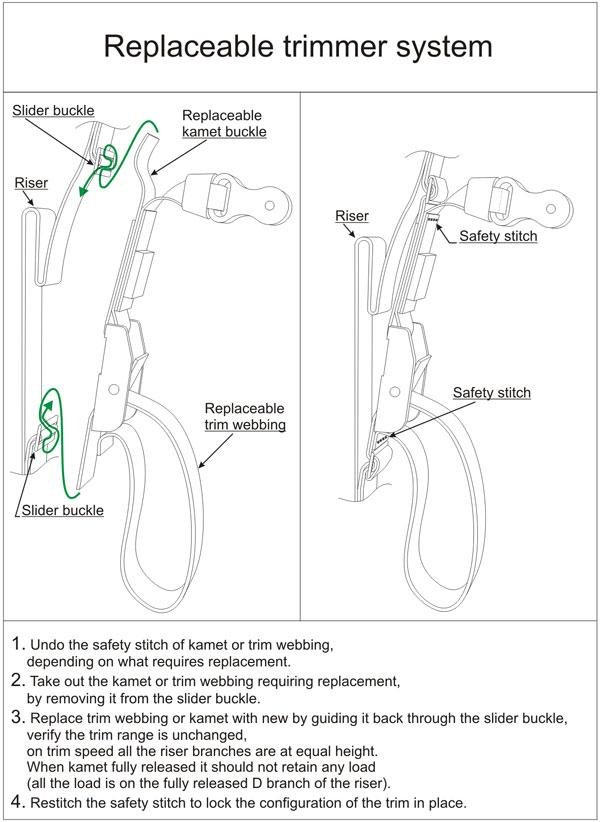

RTS – REPLACEABLE TRIM SYSTEM

APCO trim risers are designed with durability in mind; however, if you are an active pilot, you may wear out your trimmer webbings and or kamet buckles long before the risers, lines, and canopy are worn out. Most of our risers equipped with trims have the option to replace just the trim webbing and kamet buckle, which is available from your dealer or online. The user can do the replacement, however, we recommend it to be done by your dealer or another qualified person.

SRS® – AUTOMATIC STALL RECOVERY SYSTEM

IMPROVING FLIGHT SAFETY – AVOIDING STALL

SRS® is responsible for the wings ability to fly and launch at amazingly low speed despite its high wing loading, preventing the wing and pilot from stalling at critical angle of attack.

SRS® is the most effective tool in aiding automatic wing recovery in case of a stall (exclusive APCO invention – pat. pend.)

A few words on the safety of paragliding, in particular about deep stall problems and possible solutions to avoid it.

The wing design of paraglider should provide for safe flight envelope, preventing the possibility of unintended stall.

Despite this, stall can occur sometimes, but the wing should recover automatically to avoid accident.

A difficult task, – often a real headache for the designer.

APCO team encountered this problem too while developing new wings, but unlike others they took an unorthodox approach in solving the problem.

Simple, ingenious system built into the risers, allowing for instant automatic wing recovery with no pilot input designed by APCO – it is now part of many APCO wings, keeping flying safe.

Named SRS® (Automatic Stall Recovery System) – It is a typical example of APCO’s intelligent approach to problem solving and thinking out of the box.

The SRS® function is simple and makes perfect sense if you think about this.

It is only surprising that no one thought of this idea before.

In normal flight the center of pressure is near the leading edge (approximately the first third of the wing’s chord – sketch 1.)

During deep stall configuration, the wing’s center of pressure moves far back to the geometric center of the chord (sketch 2).

The principle of SRS® function is based on shifting the center of pressure when wing is stalled, creating an automatic leverage mechanism for reduction of wings angle of attack and immediate recovery from stall (sketches 3 and 4).

V-LINK

The V-links replace the traditional rapide maillon (quicklinks) connecting the lines to the risers.

The V-links are beautifully forged from 7075 T6 aircraft grade Aluminium – more resembling “jewelry” than paragliding hardware!

They utilize a geometrical lock which is sealed by a plastic insert that once put in place cannot fail, creating a fool proof mechanism.

The V-links are a pure improvement on all aspects, and prove once again that APCO Aviation is Setting Future Standards::

Strength:

Over 1,000 kg breaking load per piece.The V-links are more than two times stronger than traditional rapide maillons! The V-links also improve the breaking point of the lines themselves, creating a better and stronger connection system. The interface between the lines and the V-links spreads the load over a wider contact area, thus preventing failure at the point of concentrated load. Rapide maillon will potentially fail at the point of connection between the metal and line which is a point of load concentration. Bending tests were performed on the shape of the V-links, proving also that on this point it is better than a standard rapide maillon.

Weight:

A mere 7 [gr] per piece, the V- links weigh 50% less than a traditional rapide maillon.

Safety:

The geometrical lock is smarter and safer than a threaded nut lock on a traditional rapide maillon. With the V-link there is no option for failure such as:

Failing / forgetting to properly close the threaded nut.

Over tightening and destroying the threads.

Vibration related unscrewing and opening during flight.

Functionality:

The V-links are fool proof. Their shape and curvature sits perfectly in the fingers during inflation, improving the feel and user experience of the glider.

Design:

Ingenious. Looking at the shape of the V-link, a question of line length may arise. When closely inspected, the diameter on which the lines are supported, is changing and therefore compensating for the difference in the length of the lines. The end result is that using a V-link is identical to mounting all lines to the same point as on the rapide maillion.

Locking:

The lines are locked securely in place by a plastic insert.

The insert acts as a geometrical lock only which does not carry any load, but only seals the opening. The insert is secured into place by a snap mechanism which once installed will not come out, securing the lines in place.

BBP – AIR EXTREME BALL BEARING PULLEYS ®

Our new pulley has been specifically designed for paragliding. This is a pulley with stainless steel ball bearings, allowing the lowest possible friction – big improvement when used for Speed system on the glider and/or harness.

Weight to strength ratio is impressive, under 10 gr and designed for breaking load of up to 300 Kg. The 16 mm plastic sheave/wheel can be used with any line up to 5 mm diameter.

This pulley’s design allows connecting the pulley with either a webbing or a line.